GlobeCore anticipates the needs and preferences of its customers – by producing new equipment and upgrading the existing ones. The latest achievement is– an upgrade of bitumen plant UMBP-22.

Despite the cost of modified bitumen being more expensive than the cost of usual bitumen its use is practical due to following reasons:

- temperature resistance of road surface;

- resistance to cracking of road surface;

- reduce surface loads;

- considerable life extension of road surface.

Operating of UVB-2 UMBP-22 plant

Bitumen plant is operated by a touch screen control panel. Every part of the device can be activated separately (manual mode) and with preprogrammed algorithm (automatic mode). Control panel also displays readings of temperature parameters and bitumen pressure at different stages of treatment.

Bitumen is preheated to temperature 180°С then pumped from the boiler by external pump. Temperature and pressure parameters are regulated by controls. The flow of bitumen is divided into three parts. First part of bitumen is supplied by a dosing pump to a mixer where it mixes with polymer; second part goes to second mill for more dispersion and homogenization; and the third part is discharged back to collection tank.

Polymer is supplied onto a spiral conveyer/mixer then by horizontal conveyer it is transported into mixer of bulk and liquid materials where it mixes with liquid bitumen. Polymer supply is regulated by rotation rate of electric motor and consequently by the spiral. Dosing of polymer to the plant is set by an operator.

This blend of bitumen and polymer is pumped to a hydrodynamic mixer of the 1st stage. Plasticizer can be also added into the mixer. The mixture is then sent to a colloid mill. Mill cutters coarse grind and blend polymer granules (it is possible to control the gap) and supply the substance to second hydrodynamic mixer.

The second progressive stage consists of the same set of components. High-pressure pump of the second stage takes second part of bitumen from from a boiler and injects it under pressure into the mixer. In the mixer the concentrated polymer bitumen mixture after the first stage and the second part of pure bitumen are mixed. Then it is supplied to the colloid mill of the second stage, for the final grinding of polymer.

After the second stage the modified bitumen is supplied for maturing (storage) to collection tank.

After completion of process the plant initiates algorithm for flushing with fresh bitumen to avoid hardening of left over components.

Specifications of plant UMBP-22 (upgraded)

| Parameter |

Value |

| 1. Capacity, ton/hour, minimum |

16 (max 20) |

| 2. Amount of polymer per 1m³ bitumen, kg |

10…60 |

| 3. Amount of plasticizer per 1 m³ |

10…100 |

| 4. Amount of adhesive additive per 1 m³ bitumen, litters (max) |

10 |

| 5. Mode of operation |

|

| 6. Nominal power, kW |

|

|

-mill |

2х55=110 |

| -1st bitumen pumps |

5,5+18,5=24 |

| -2nd bitumen pump |

18,5 |

| – polymer mixer |

11 |

| -plasticizer supply pump |

4 |

| -adhesive additive supply pump |

0,37 |

| -screw conveyor drive |

3 |

| -spiral conveyer drive |

0,25 |

| -screw mixer drive |

3 |

| -total |

175 |

| 7. Electric current parameters |

|

– voltage, V |

380 |

| – AC frequency, Hz |

50 |

| 8. Dimensions, mm max |

|

– length |

5700 |

| – height |

2420 |

| – width |

2140 |

| 8. Weight, kg, max |

7500 |

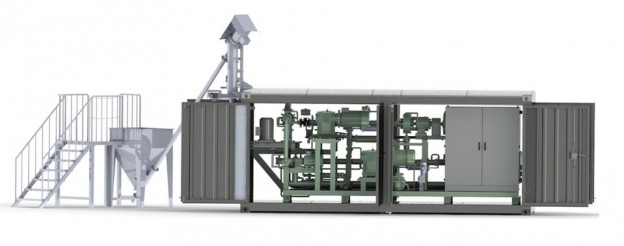

UVB-2 UMBP-22 bitumen plant assembly components

The bitumen plant is supplied mounted on a frame complete with spiral conveyor for polymer supply and quantity calibration and horizontal belt conveyor. Also it includes a loading platform.

UVB-2 Upgrading

Bitumen plant is now equipped with temperature and pressure control units of input bitumen, regulating these parameters both before and during process.

Inlet is also equipped with bitumen dosing pump adjusting bitumen amount and frequency with polymer supply in mixer.

Also UMBP-22 was upgraded with an additional polymer mixer. This is a rotor-type aggregate, belt driven by electric motor. Polymer is supplied from a dosing tool into a mixing chamber -a screw conveyer where it is wetted by bitumen from dosing pump and discharged from mixer to pump for further dispersion in the first stage.

There is a new HTF (heat transfer fluid) circulation pump. It preheats a plant before starting work – preparation for work (warming) takes much less time.

Bitumen plant has standard transportation size. Equipment inside is laid out to give access to all controlling devices As a result the operating safety of UMBP-22 has been improved.

Container case has shutters at all sides – this gives not only convenient access to plant aggregates but also ensures additional air circulations preventing pumps and engines overheating.