Bitumen emulsion units can be divided into two groups

(1) continuous units; and

(2) batch units.

The continuous bitumen units do not include dosing containers. Therefore, bitumen and emulsifier solution are supplied directly from the transport containers. Emulsifier solution is prepared by injecting emulsifier, stabilizer and acids into the water line that creates the reaction between the emulsifier and the acid.

Water heating is realized by a special continuous heater. If you decide to buy a continuous bitumen unit, you will have to use an emulsifier that is easily dispersed in water to ensure a fast reaction with the acid.

Acid metering is realized by a special pH sensor mounted into a colloid mill.

Bitumen and solvent are being continuously supplied to a colloid mill.

Batch bitumen units are equipped with dosing tanks to prepare solvent emulsifier. It is desirable to use a container with a level indicator to meter huge volumes of bitumen and water. Small volumes of substances (solvent and chemicals) are metered by accurate metering units.

Then they are supplied by gravity through a colloid mill until the dosing tank becomes empty.

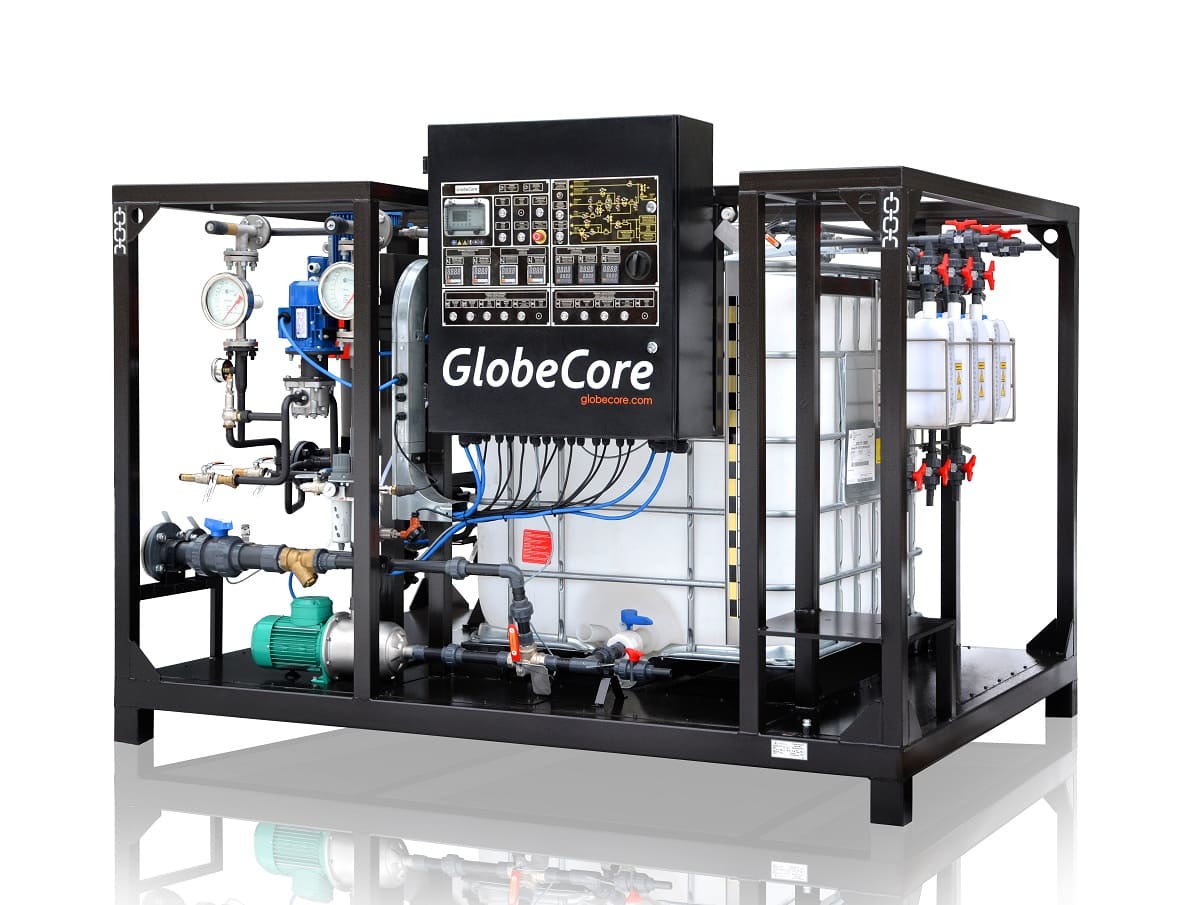

GlobeCore is a manufacturer of batch bitumen emulsion units designated as the UVB-1 system. The main benefit of these units is that they cost significantly less than continuous bitumen units.

Additionally, GlobeCore equipment is capable of producing both cationic and anionic bitumen emulsions that meet the worldwide standards of the international road construction industry.